Build a hardwall cleanroom specific to your needs with our modular systems.

What Is a Modular Hardwall Cleanroom?

A modular hardwall cleanroom is a controlled environment with a flexible, expandable design. “Hardwall” refers to the solid, rigid construction and materials used for the cleanroom. These types of cleanrooms are most commonly used in industries like pharmaceuticals, biotechnology, electronics, aerospace and others where stringent contamination control is needed.

For many seeking easy-to-build solutions, Gerbig’s AireCell® system features modular hardwall cleanrooms that are the best fit for a number of reasons:

- Patented, easy-to-install aluminum extensions combine with any ¼” panel for a variety of applications

- Easy reconfiguration or expansion to help you stay flexible while minimizing downtime

- The ability to integrate with other systems or materials

- Adjustable footing to keep level even when the floor isn’t

Explore our hardwall cleanroom products and solutions and contact Gerbig Cleanrooms for more information on our hardwall modular cleanrooms.

What Is the Difference Between Hardwall and Softwall Cleanrooms?

Hardwall cleanrooms feature solid, rigid walls made of rigid panels or other strong materials like steel, providing structural stability and support. On the other hand, softwall cleanrooms have flexible, curtain-like walls typically made of vinyl. Hardwall cleanrooms offer greater durability, better noise isolation and enhanced cleanliness control due to their solid construction, while softwall cleanrooms are easier to transport and set up.

Not sure which one you need? Consider the following:

Project Duration

- If your project is long-term, it’s better to choose a hardwall cleanroom due to its durability and longevity

- If your project is short-term, it’s better to choose a softwall cleanrooms for its flexibility and cost-effectiveness

Budget

- If you have the budget, choose hardwall cleanrooms for their expandable nature, structural stability and ease when cleaning

- If your budget is more limited, softwall options are more accessible

Your Unique Needs

- If consistency and strict environmental control are top priorities, hardwall cleanrooms will be a better option for your needs

- If mobility and swift implementation are top priorities, softwall cleanrooms will better fit your needs

Advantages of Hardwall Modular Cleanrooms

Scalability and Flexibility

- Easy expansion possibilities

- Adaptable designs for various needs

Quick Installation

- Less downtime during setup

- No need for major construction

Durable and Long-lasting

- Made of robust materials

- Withstand various environmental conditions

Enhanced Contamination Control

- Superior air filtration systems

- Better control over environmental parameters

Cost-Effectiveness

- Reduced maintenance costs

- Energy-efficient designs

Gerbig’s Modular Hardwall Cleanroom Systems

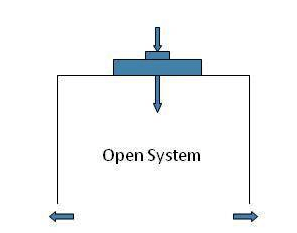

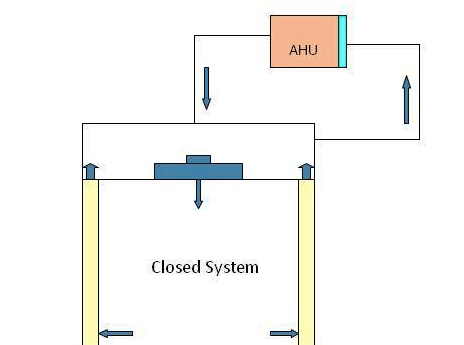

Depending on the use of your hardwall cleanrooms — and the room in which you’re putting the cleanroom — you will have to decide which air-flow system to implement: open or closed loop.

The open-loop cleanroom system doesn’t require ductwork or a plenum wall system, which can be an advantage or a disadvantage depending on your needs. The closed-loop system has the ability to control humidity, and uses a double-hung ceiling or plenum system.

Open Loop Modular Hardwall Cleanrooms

- In the open-loop system, the HEPA-filtered air exits the room at the floor and returns to the fan-filter unit freely

- Reduced cost because there are no return air chases, ductwork, or plenum

- With open-loop cleanrooms, room pressure is determined by the pressure loss of the air passing through the wall grilles or under the wall panels

- The disadvantage to the open-loop concept is the absence of humidity control which can’t be used if the ambient area has no air conditioning.

Closed Loop Modular Hardwall Cleanrooms

- In closed-loop systems, HEPA-filtered air is contained within the hardwall cleanroom envelope

- Once air is returned to the chase or riser, there are two possible methods for completing the air circuit: to duct the air from the wall riser to the fan-filter unit or back to the AHU

- The advantage of using this system is that the humidity can be adjusted to a different value than the ambient area

- Uses a double-hung ceiling or plenum system

Open Loop

Closed Loop

Open Loop Louvers

Integrated Cleanroom

Find a Solution Today

Tell our team about your project and we’ll find you the perfect product for your needs.