Gerbig Certification Division is part of CSI Testing to become the largest independent certification provider in the upper Midwest — now serving customers under the CSI Testing name.

You can still receive the exceptional testing standards, expertise, and reliability you’ve come to rely on from Gerbig Certification, just in a new place. Visit CSI Testing’s website to learn more. Gerbig is still your trusted partner for the construction of cleanrooms, manufacturing, and filter providers.

Gerbig’s Cleanroom Solutions & Certification

Gerbig Cleanrooms has been the leading cleanroom manufacturer based in Minneapolis, MN since 1985. Providing modular cleanrooms to customers domestically and abroad, our innovative technology has set federal cleanroom standards. We offer top-of-the-line products and walkthrough solutions.

AireCell® Cleanrooms & Wall Partitions

AireCell® modular cleanrooms and wall partitions are constructed with anodized aluminum framing that is designed and manufactured by Gerbig Cleanrooms. The AireCell® system allows for virtually any size, class and configuration to be accommodated. Cleanrooms can be free-standing or integrated into the building structure. Our flexible design capabilities reduce installation time, so walls and rooms can be assembled quickly and efficiently.

Learn More

AireCell® Products

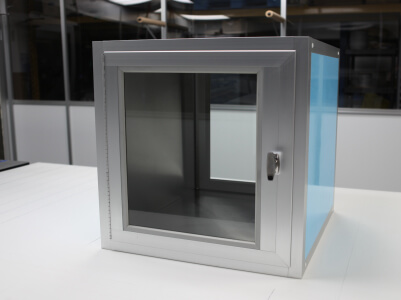

Gerbig Cleanrooms manufactures affordable pass-thru units, workstations, wardrobes and custom enclosures. Gerbig Cleanrooms is also a distributor of HEPA Filters and other cleanroom components. Our team has been designing modular cleanrooms for 30 years in virtually all industries requiring contamination control. Let us put our experience to work for you.

Learn More

Cleanroom Certification

For more than 25 years we have been certifying cleanrooms and cleanroom equipment from ISO 3 to ISO 9 for a variety of industries’ facilities, from industrial to scientific. Our Technicians have worked on projects all over the world. Enlist Gerbig’s expertise to ensure regulatory compliance.

Learn More